Filter Bags

Filter Bags

Standard Filter Bag

We offer high quality liquid filter bags to fit standard size filter vessels, as well as custom designed products where requested. The constituent materials have been chosen for their purity, consistent high quality and repeatable performance. Filter bags are available in traditional stitched form or with a fully welded construction, and are fitted with a comprehensive choice of rings.

- 7” or 4” galvanised Steel rings (or stainless steel) which fit universally into all filter housings. Polypropylene rings and stainless steel bands are also available.

- Custom designed moulded Welseal (polypropylene or polyester) welded rings, giving more positive sealing, needle hole elimination and lifting handles for faster and easier bag installation and replacement. A Welseal ring product is fully combustible.

- Custom designed positive sealing Santaseal moulded ring, for applications where high temperature or chemical resistance properties are required.

ulti Layer Felt Filter Bags

Multi Layer felt filter bags provide graded density, multi stage depth filtration in a single filter bag. A high dirt loading capacity and superior filter bag lifetime is achieved by selecting the optimum micron ratings of the pre-filtration and final filtration layers in accordance with the needs of the filtration process.

Multi Layer filter bags can be produced with 2 or 3 layers of polypropylene or polyester needlefelt, and to further enhance performance, a layer of extended life felt can be incorporated. An optional mesh exterior cover can also be provided.

Mesh Filter Bags

Custom Made Filter Bags

High Efficiency Filter Bags

High efficiency bags are available rated at 1-25 micron, and perform to efficiencies >95%.

The filter bag consists of up to 4 layers of melt blown polypropylene media, including an outer cover to prevent fibre migration into the filtrate as well as providing added support to the filtration media. The high density of small diameter fibres compared to that of a standard needlefelt enhances particle retention, leading to superior, highly efficient filtration.

Filter Cartridge

Wound Filter Cartridges

Wound filter cartridges are economical, nominal rated depth filters. They are produced from a continuous fibre yarn spirally wound around a central support core.

The computer controlled winding pattern ensures precise, reliable and repeatable particle removal performance. Wound filters feature a graded density construction, enabling progressively smaller particles to be captured through the depth of the filter media. The result is a high dirt holding capacity filter which has a low pressure drop.

Wound filter cartridges are most commonly made from polypropylene yarn wound on to a polypropylene core, but for applications where chemical compatibility or operating temperature restricts the use of polypropylene, other fibres such as cotton, glass, polyester, nylon or polyphenylene sulphide (Ryton) can be offered wound on to a stainless steel core. We also offer the option of a glass reinforced polypropylene core which provides superior strength and permits higher operating temperatures (up to 100°C)

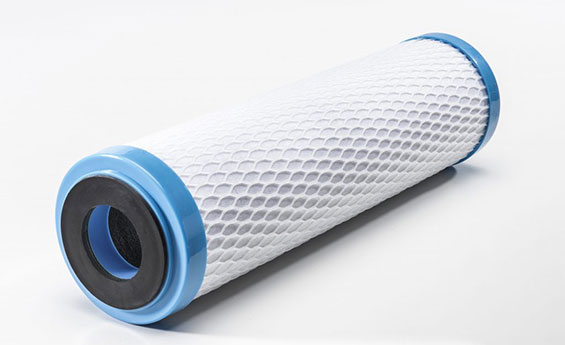

Proxis Melt Blown Cartridges

Melt blown cartridges are nominal rated with a particle removal efficiency of 90% at the designated micron rating.

Melt blown cartridges are absolute rated with a particle removal efficiency of 99.9% at the designated micron rating.

Melt blown cartridges have a 100% polypropylene construction, and feature an inner core to enhance mechanical strength. They have a graded density structure, and have no contaminant downloading even at high differential pressures.

Pleated Filter Cartridges

High Flow Pleated Filter Cartridges

High flow pleated cartridges combine the best of pleated and large diameter cartridges.

The unique multi-layered construction provides absolute rated particle retention across a wide range of flow rates with efficiencies of 99.98% at the designated micron rating.

The large diameter yields much higher flow rates compared to traditional 2.5” diameter filters, permitting use of fewer elements and lowering capital expenditure.

Contrary to standard filter cartridges, high flow pleated filters most commonly have an inside to out liquid flow direction, enabling particles to be collected on the cartridge’s interior. The cartridges have an injection moulded top end cap with integral moulded handle to assist cartridge removal.

PES Membrane Filter Cartridges

Polyethersulphone membrane filter cartridges are designed to provide reliable sterilizing filtration for a wide variety of applications including water filtration, removal of spoiling micro-organisms in beverages, and filtration of pharmaceutical products.

Stringent quality control standards assure effective, consistent filtration performance and controlled pore sizes. PES membranes are inherently hydrophilic, and can therefore operate at high flow rates with a low differential pressure. Polypropylene support layers are present to provide mechanical strength and additional contaminant holding capacity.

ECB and SCB Carbon Filter Cartridges

Carbon Wrap Filter Cartridges

The Carbon Wrap (CW) series features powder activated carbon (PAC) impregnated into a cellulose fibre media, removing sediments and other fine particulates throughout its depth. The CW series combines the advantages of both a high dirt-loading depth cartridge with the odour, discolouration and chlorine reduction capabilities of PAC.

The carbon impregnated sheet is wrapped around a polypropylene support core, supported by an outer layer of polyethylene netting.

Metallic Filter Cartridges

Metallic filter cartridges are a re-usable surface filter manufactured using stainless steel wire mesh filter media. They are designed to withstand demanding working conditions as well as strong cleaning procedures such as backwash or chemical treatment. They can also be cleaned in an ultrasonic bath, with high pressure water or by simply brushing the surface of the wire mesh.

Stainless steel has a wide chemical compatibility, and use at high temperature can be achieved in relation to the material joining the end cap. Their low pressure loss also makes them suitable for use with high viscosity fluids.

Our range has two construction options, either non-pleated or pleated which provides enhanced surface area and filter lifetime.

Request a quote: